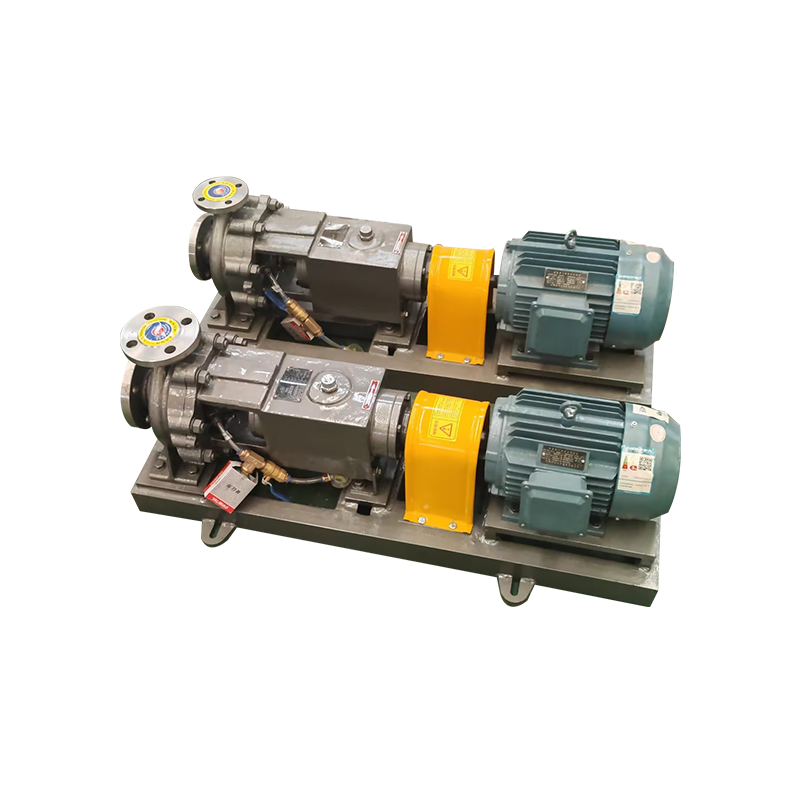

IH Type Horizontal Chemical Centrifugal Pump

Cat:Chemical Process Pump

The IH type chemical centrifugal pump is a single-stage single-suction (axial suction) cantilever centrifugal pump, which is used to transport liquids...

See DetailsIn industries like petrochemical refining and alkali production, pumps often operate under extreme conditions—high pressures, fluctuating temperatures, and chemically aggressive environments. But how do our Chemical Alkali Pumps hold up when the heat is on, and the pressure is pushing the limits? The answer lies in their robust design and the specialized materials chosen to ensure long-lasting performance, no matter how harsh the conditions.

Our pumps are built to handle the kind of stress that comes with high-pressure systems or processes where temperatures fluctuate dramatically. Whether it's for transferring petrochemical products or handling alkali solutions at high temperatures, these pumps are equipped with reinforced structural components that allow them to withstand the stress of constant pressure without compromising on efficiency. Materials like high-grade stainless steel, titanium alloys, and advanced fluoropolymer coatings are used in critical parts, ensuring that the pump’s integrity is maintained even when exposed to extreme heat or corrosive substances.

For processes where temperatures vary—such as those seen in alkali production or electrochemical processes—the pump’s design takes into account the expansion and contraction that occurs. We use temperature-resistant seals and flexible casing structures that accommodate these changes without creating gaps that could lead to leaks or system failure. In petrochemical applications where the temperature swings from high to low, these pumps maintain a reliable seal, which is crucial in ensuring that volatile chemicals, such as acetaldehyde or alkyl benzene, are transported without any risk of leaks.

Under high-pressure conditions, especially in environments where thick slurries or highly concentrated chemicals are pumped, the impeller and casing are designed with heavy-duty construction to prevent deformation or failure. The high-strength alloys used in the pump shaft and motor components are capable of handling these pressures without compromising on the efficiency of fluid transfer. The pump's impeller is engineered to maintain optimal performance even when the pressure is at its peak, ensuring smooth operation and minimal wear over time.

Perhaps most important of all, these pumps are designed for continuous, long-term operation. Whether it's in an alkali production plant where caustic soda needs to be moved at high pressure, or in petrochemical refineries where temperature fluctuations are constant, the durability of the pump’s internal components ensures that it can run tirelessly without the risk of failure. Regular maintenance and easy-to-access parts further extend the lifespan of the pump, keeping it running at peak performance in even the toughest operating environments.

Our Chemical Alkali Pumps are built to take on extreme pressures, temperature variations, and the rigors of continuous industrial operations. With advanced materials, high-strength construction, and thoughtful design, these pumps ensure that your process runs smoothly, safely, and efficiently, no matter the conditions. Whether in a petrochemical or alkali production setting, you can count on these pumps to perform reliably when the pressure is on and the temperature fluctuates.