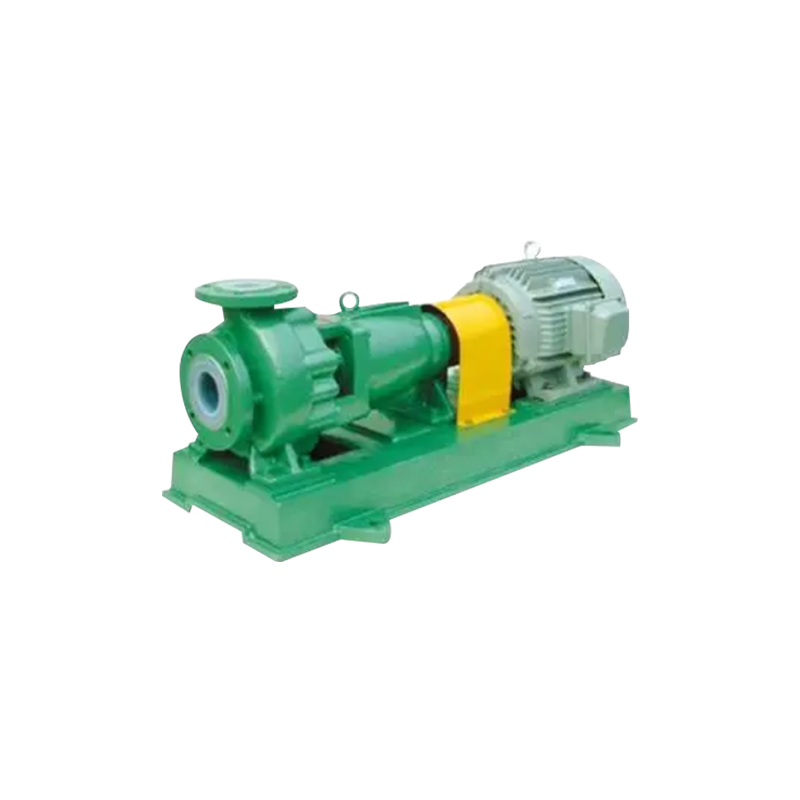

HJ Chemical Process Pump

Cat:Chemical Process Pump

1. Overview of the HJ chemical process pump HJ corrosion-resistant chemical process pump is a single-stage single-suction cantilever centrifugal pump....

See DetailsIn industries where aggressive, corrosive fluids need to be transported or processed, the right pump can make all the difference in ensuring reliability, safety, and longevity. Fluorine lined axial flow pumps have emerged as a critical solution for handling such fluids, offering enhanced resistance to corrosion and wear. These pumps are designed to meet the unique challenges of industries such as chemical processing, water treatment, and petrochemicals, where fluid properties can be harsh and demanding.

Fluorine-lined axial flow pumps are specially designed pumps where the internal components that come in contact with the fluid are coated with a layer of fluorine-based materials, typically PTFE (Polytetrafluoroethylene) or PFA (Perfluoroalkoxy). These materials offer unparalleled resistance to chemical corrosion, high temperatures, and aggressive fluids, making them ideal for handling substances that would otherwise degrade or damage traditional pump materials.

Corrosion Resistance: One of the primary reasons for using fluorine-lined axial flow pumps is their exceptional resistance to corrosion. Fluorine-based materials, such as PTFE, are inert to most chemicals, including acids, alkalis, and solvents. This makes fluorine-lined pumps perfect for industries that deal with highly corrosive fluids like hydrochloric acid, sulfuric acid, or chlorine solutions.

High-Temperature Tolerance: Fluorine-lined axial flow pumps can operate efficiently at higher temperatures compared to traditional pumps. PTFE and PFA materials can withstand temperatures ranging from -200°C to 260°C, depending on the specific fluoropolymer used. This thermal stability is crucial for handling fluids that require high-temperature processing, such as molten chemicals or hot water in industrial applications.

Enhanced Durability: Fluorine materials are not only resistant to corrosion, but they are also extremely durable and wear-resistant. This longevity minimizes the need for frequent maintenance or part replacements, providing significant cost savings and increasing the overall efficiency of the pumping system.

Smooth Surface Finish: The fluorine lining provides a smooth, non-stick surface that reduces friction and ensures that fluids can flow freely without obstructions. This smoothness also reduces the buildup of deposits or scaling inside the pump, further contributing to its efficiency and longevity.

Low Maintenance: The robust nature of fluorine linings reduces the need for frequent cleaning and maintenance. This is especially important when dealing with highly corrosive or toxic materials, as it helps minimize downtime and ensures that the pump continues to operate at peak efficiency.

Chemical Inertness: The chemical inertness of fluorine linings means that the pump can safely handle a wide range of aggressive and reactive chemicals without the risk of material degradation. This is especially important in applications where product purity is critical, as there is no risk of contamination from the pump materials.

Fluorine lined axial flow pumps are used in various industries where corrosive, aggressive, or high-temperature fluids need to be transported. Below are some key applications:

Chemical Processing: In the chemical industry, pumps are often required to handle acids, alkalis, solvents, and other aggressive chemicals. Fluorine-lined axial flow pumps are essential for transferring these substances without the risk of corrosion or damage to the pump components. They are commonly used in reactors, distillation columns, and chemical mixing tanks.

Petrochemical Industry: The petrochemical industry deals with a range of aggressive fluids, including crude oil, natural gas liquids, and refined chemicals. Fluorine-lined pumps are ideal for safely transporting these substances, as they prevent the degradation of the pump materials and ensure long-term reliability.

Water and Wastewater Treatment: In water treatment facilities, fluorine-lined pumps are used to transport chemically treated water or wastewater containing corrosive chemicals such as chlorine or sulfuric acid. These pumps are also used in desalination plants, where high levels of salinity can cause rapid corrosion of standard pump materials.

Pharmaceutical Industry: The pharmaceutical industry requires pumps that are able to handle sensitive and highly reactive chemicals without contamination. Fluorine-lined axial flow pumps meet these requirements, as their smooth, non-reactive surfaces prevent contamination during the pumping of active pharmaceutical ingredients (APIs) or other sensitive compounds.

Food and Beverage Processing: In food and beverage manufacturing, fluorine-lined pumps are used to transport hot, acidic, or chemically treated liquids without risk of contamination. Their ability to maintain product purity and withstand harsh cleaning agents makes them ideal for these industries.

Electronics Manufacturing: Fluorine-lined axial flow pumps are used in the electronics industry to handle the transportation of chemicals such as etchants, developers, and other substances used in semiconductor manufacturing. The chemical resistance and non-contaminating nature of the fluorine lining ensure that the pump does not introduce impurities into the delicate manufacturing process.

Increased Operational Efficiency: The corrosion resistance and durability of fluorine-lined axial flow pumps ensure smooth and uninterrupted operation, even when dealing with aggressive or high-temperature fluids. This increases the overall efficiency of the industrial process, reducing downtime and maintenance costs.

Longer Service Life: The inherent strength and durability of fluorine coatings extend the lifespan of the pump, reducing the frequency of replacements or repairs. This leads to long-term cost savings and a more sustainable pumping solution.

Enhanced Safety: Given their ability to safely transport toxic or hazardous fluids without degradation or leakage, fluorine-lined axial flow pumps enhance safety in industrial settings. This reduces the risk of environmental contamination or worker exposure to harmful chemicals.